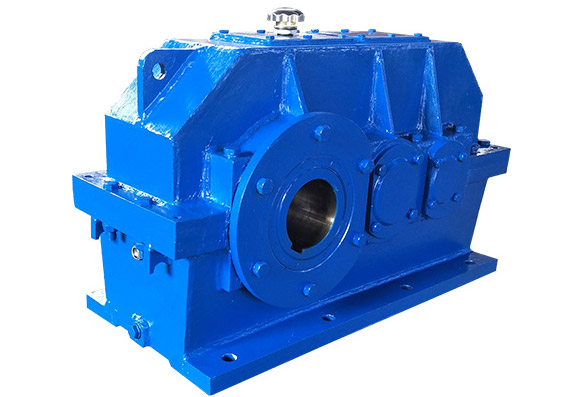

XNUMX. Structure in situ

The entire transmission device of the planetary cycloid reducer can be divided into three parts: the input part, the deceleration part, and the output part.One is installed on the input shaft; a double eccentric sleeve with a displacement of 180' is installed on the eccentric sleeve. Two roller bearings called rotating arms are installed on the eccentric sleeve to form the H mechanism. The center hole of the two cycloidal needle wheels is the eccentric sleeve. The raceway of the swing arm bearing is meshed with a set of circularly arranged needle teeth on the needle gear to form an internal meshing reduction mechanism with a tooth difference of one tooth. (In order to reduce friction, the speed ratio is small. In the reducer of, the needle tooth is equipped with a needle tooth sleeve).

When the input shaft rotates with the eccentric sleeve, due to the characteristics of the upper tooth profile curve of the cycloidal needle wheel and its needle test _ limited by the needle gear _ upper needle tooth, the movement of the cycloidal wheel becomes the existing revolution There is also a self-rotating plane W mechanism rather than the cycloidal wheel. When the input shaft rotates forward, the eccentric sleeve also rotates once. The cycloidal wheel rotates in the opposite direction through a toothed arm to reduce speed. Then, with the help of the W output mechanism, The low-speed rotation motion of the cycloid pin wheel is transmitted to the output shaft through the pin shaft, thereby obtaining a lower output speed.

XNUMX. Features

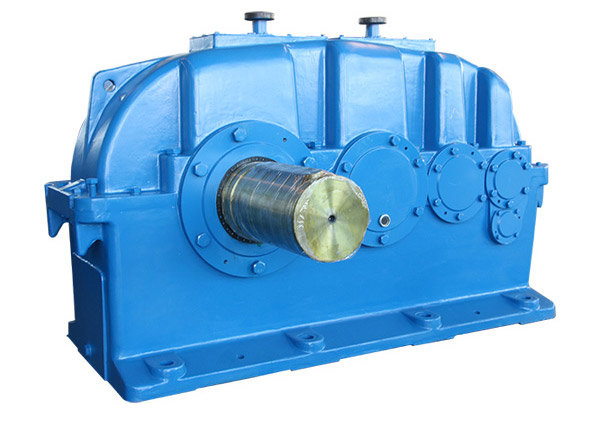

△High speed ratio and high efficiency

Single-stage transmission can achieve a reduction ratio of 1:87, and the efficiency is above 90%. If multi-stage transmission is used, the reduction ratio is greater.

△Compact structure and small size

Due to the adoption of the planetary transmission principle, the input shaft and output shaft are on the same axis, so that the size of the model can be as small as possible.

△ Smooth operation and low noise

Cycloid needle teeth have a large number of meshing teeth, a large overlap coefficient and a mechanism of mechanical balance, which minimizes vibration and noise

△Reliable use, long life expectancy

Because the main parts are made of bearing steel material, the high strength building is obtained by quenching treatment (HRQ58 (62), and part of the transmission contact uses rolling friction, so it has a durable life.

△Reasonable design, convenient maintenance, easy disassembly and installation, minimum number of parts and simple lubrication make the cycloid reducer deeply trusted by users.