The working environment of many processing and production units is very bad. Not only the indoor temperature is high, but also because many materials need to be processed, it is easy to cause confusion in the processing environment. If you do not pay attention to environmental hygiene during work, dust and impurities can easily enter the planetary cycloid Inside the pinwheel reducer. If these dirt is mixed into the oil, it will have an adverse effect on the efficiency of the reducer. Therefore, in such a working environment, the quality of the oil needs to be checked regularly during the use of the reducer, and it is also necessary to periodically check the quality of the oil during the use of the reducer. Replace the oil with the reducer. Generally, when checking the quality of the oil inside the reducer, you should pay attention to power off the reducer and check when the oil temperature is cooled. This will ensure the safety of the inspection work. When replacing the oil with the reducer When the oil temperature is cooled, the viscosity of the oil may be too large, and it may be difficult to change the oil at this time. Therefore, when changing the oil, you must first cut off the power of the reducer. When the oil temperature has a certain amount of heat, the oil needs to be replaced. It can make the oil change work easier and smoother.

When changing the oil, you need to put an oil pan under the oil drain plug, then open the oil level screw plug, you need to open the ventilator and the oil drain plug, and then you need to open the oil in the reducer... Remove all the oil and drain the oil Then check the impurities inside the reducer. If you find that there are impurities in the reducer that have not been cleaned up, please clean it immediately to avoid blockage when the reducer is working. When injecting new oil into the reducer, you should replace the specified type of oil. Do not pour excess during the injection process If the amount of oil is too much, it may cause oil leakage during operation. The oil level on the oil level plug should be checked during the injection process.

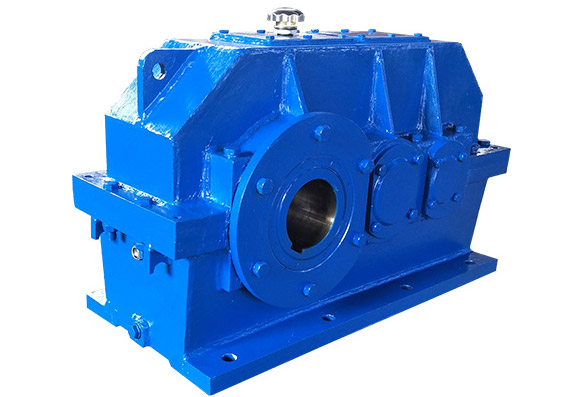

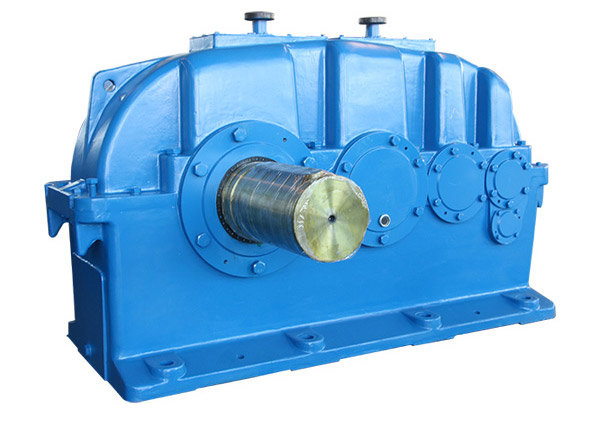

When replacing the planetary cycloidal pinwheel reducer oil, it must be replaced by professionals, and the oil should be replaced according to the working steps and operating specifications. The planetary cycloidal pinwheel reducer has been developed for decades from its initial production. At present, Nuo MAN Group has a high reputation and is a brand recognized by everyone. However, the use of this type of reducer in China began in the mid-20s. Norman gearboxes are widely used in various applications, especially for power transmission Technology. More than one piece has been sold so far. Its design principle is very technical, and the application is mainly a modular combination system. This feature is very significant and has many advantages. The most intuitive feature is the combination of motors and the installation angle Flexibility. People prefer its structural settings, so its usage rate is very high.

However, if you want to apply this reducer, you need to have certain technical requirements. Its component combination needs to be executed in strict accordance with the operating system. When people use it, they can pay attention to the following issues.: First, you need to pay attention to the output speed. Many people do Hope the value of this indicator is lower, but I don’t know how to deal with it. Specifically, we can consider the connection mode, especially the power of the two gears to achieve this requirement. At the same time, the power plan should be paid attention to, so the limit must be considered Output torque. When discussing issues, many people in life often have direction deviations. For example, the motor power requirements will be considered too much. This calculation method is unreasonable.

Secondly, during the installation process, we should also pay attention to the operational configuration requirements. The installation of the transmission components is a bit troublesome, so many people use very rough methods to install, such as using a hammer. This method is easy to cause damage to the parts, so it is strictly forbidden. We A more convenient solution can be found, which can not only play the role of assembly fixtures, but also use internal threads to achieve installation. This improves installation efficiency without damaging specific equipment components. This skill is what a general operator should have Knowledge and ability.

Of course, during the installation process, people still have questions about whether there are strict requirements for coupling. Many people think it is necessary to choose a fixed type. In fact, this often affects the load capacity, which is not conducive to the long-term use of the bearing. This is usually a lot of The reason why the machine breaks down. The last point is to pay attention to the reliable characteristics of the installation. The foundation you choose must be stable enough. If you find excess grease, be sure to clean it, otherwise it will cause the machine to loosen. This is also the installation of any equipment One point that must be completed before. If the basic settings are unstable, subsequent use will affect continuous use.

The above is an introduction to the knowledge of planetary cycloid reducer, and introduces some professional considerations. Therefore, when learning technology, we must start with the most basic installation method, so that we can play the best role of the reducer. It is good to check the instructions to understand the machine more intuitively. It is best to be inspected by an inspector after installation, which will ensure the quality and standards of the installation. In order to make the machine use for a long time, necessary maintenance and maintenance work is essential.