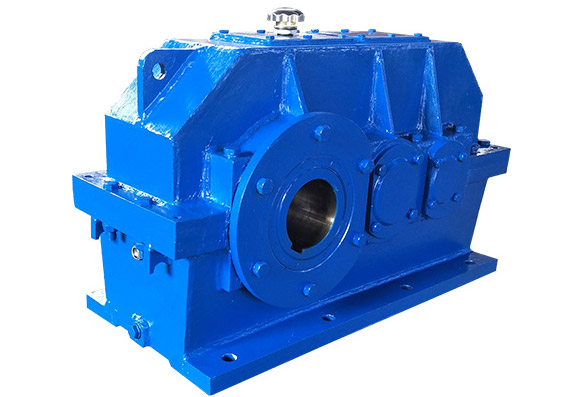

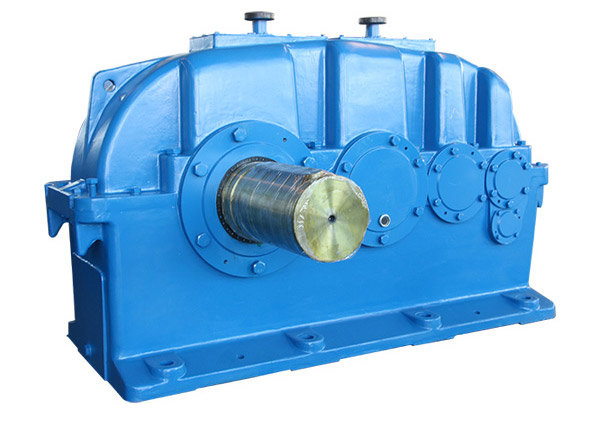

蜗轮丝杆升降机壳体和螺纹部分在外部处理和使用期间暴露,并且由于各种因素不可避免地生锈。在这种情况下,如何处理电梯电梯的表面腐蚀。

We know that the shell of the screw jack is mainly a ball screw elevator made of cast steel worm gear crane.The screws are mostly made of 40Cr.When exposed to humid air, these materials are exposed to the air and rust.This requires us.In normal use, pay attention to timely inspection and maintenance.For equipment that has rusted, we can use the following methods to remove rust:

1. It is not serious to deal with rust, it can be polished and rusted, and then coated with anti-rust oil.The problem with the second method is that the sandpaper loses a lot of the screw jack itself.

2. Low-pressure water mill derusting: the method of grinding and rusting the screw by the blow of low-pressure water jet and abrasive promotion.The advantage is that the damage to the data is very small, but the water has some damage to the electronic equipment.Removable screw jack.

3. Small wind or electric dust removal: Friction or electromagnetic effect occurs when the atmosphere is compressed, which can cause friction, grinding and rust on the outside of the screw jack. It can be used for the detailed instrument push rod or micromanipulator of the necessary screw jack.

4. Chemical descaling: It is important to adopt descaling methods and apply the chemical reaction between the acidic materials of the screw jack and the metal parts to remove the rust outside the rust of the push rod.This method is mainly used for large machine screw jacks.In the application process, care should be taken to shield electronic equipment and other detailed equipment to prevent acid corrosion.

In fact, in the application process, we only need to pay more attention to safety protection and invent real-time repair and damage to prevent equipment rust.